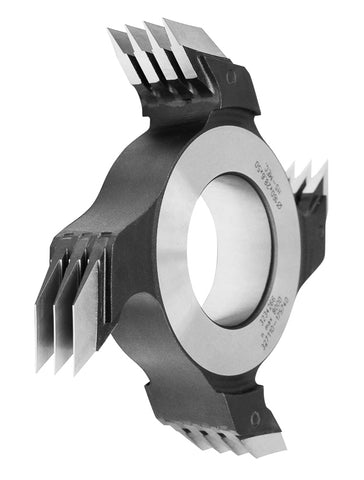

Finger Joint Tooling

Products

Affiliate Sites

As part of the Burton Mill Solutions family of companies, we understand that each and every one of your jobs is never just a one step process. With our strategic network of industry related companies, we’re certain that we can provide you with the best quality tools that you need.

Contact

Global Tooling &

Supply

950 International Way

Springfield, OR 97477

Phone: 541-302-1366

Fax: 978-424-9063

© 2024 Global Tooling & Supply. All Rights Reserved. Site Design.